The Main Topic To Preparation For Stickers

1. How to prepare artwork for stickers?

2. How to calculate the sticker format for rounded stickers or die-cut stickers?

3. What are the differences of the sticker material types

1. How to prepare artwork for stickers?

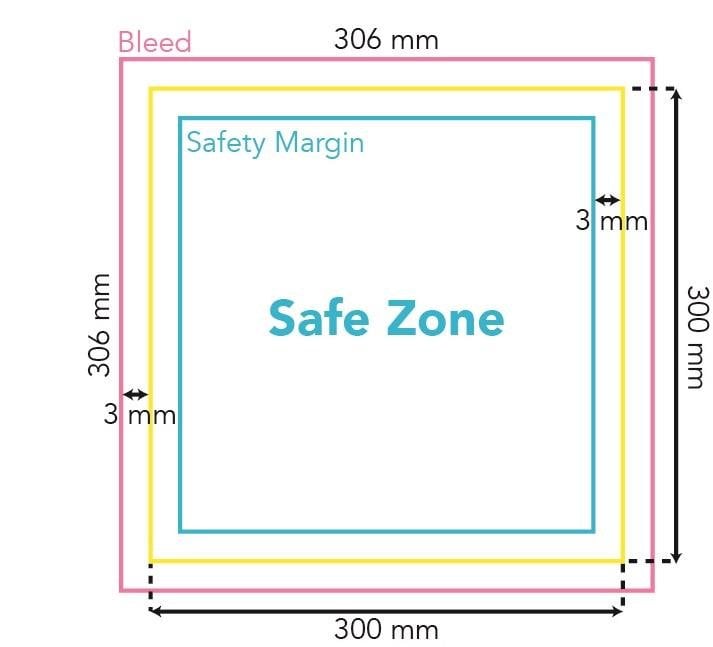

Safe Zone: all elements of your artwork must be within the Safety Margin of 3mm from all sides of the die-line.

Full Bleed: Expand your background design by 3mm from all sides of the artwork height and width dimensions to ensure sufficient bleed

Please note that custom size formats need to be at least 3 x 3 cm for rectangular shapes or need to have a minimum diameter of 3 cm for round shapes.

Texts should be at least 2 mm in height, to ensure that they will appear sharp on the printed sticker.

Please consider using 100% of single color, C, M, Y, or K, for small texts for sharper printing results.

Please upload three files:

○ File containing both artwork and die-cut in vector format

○ Artwork file

○ Die-cut line file in vector format

2. How to calculate the sticker format for customized shape or round stickers?

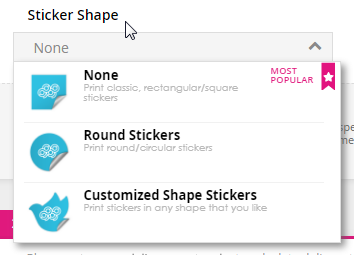

First step, you need to select the Sticker Shape option for Customized Shape Stickers.

Afterwards you have to enter your sticker format by clicking the Need a custom format button. Example 2 explains you how to calculate your sticker format in the case of customized shape sticker formats.

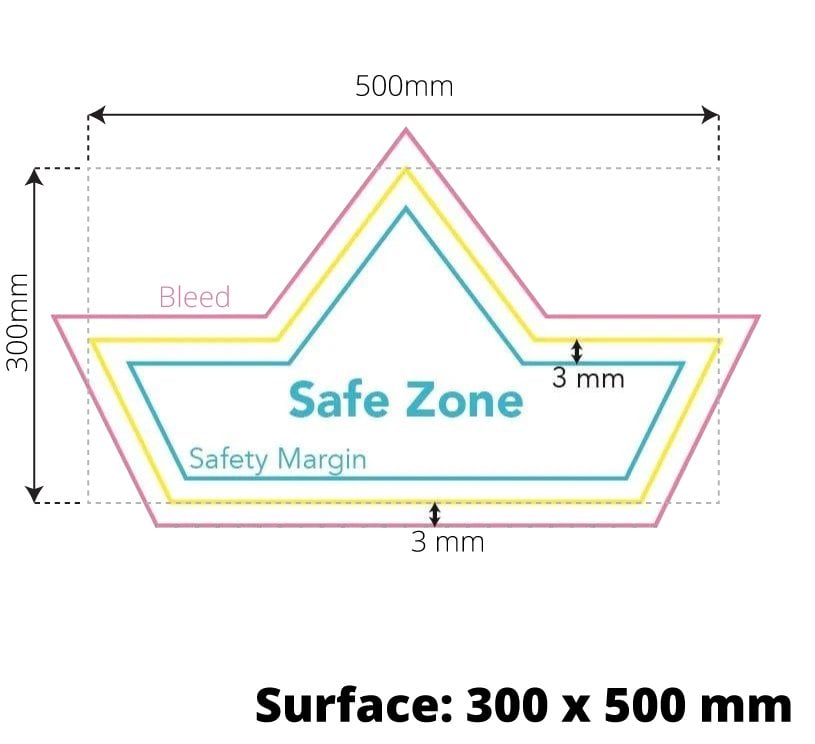

In the graphic below a customized shape sticker is depicted. It is very important here again to respect the safety margin and bleed of 3mm as depicted in the graphic. In order to calculate the surface of custom format stickers you have to draw the smallest rectangle possible around your custom design which still includes your whole artwork with bleed. The surface of this respective rectangle represents then the surface of your custom format sticker. In the Example 2 this is a rectangular of width 5 cm and height of 3 cm.

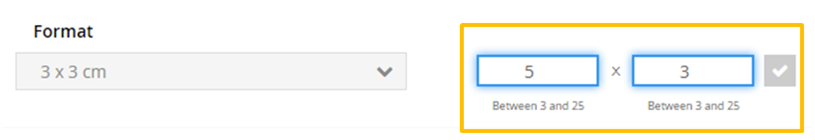

By now, you know the custom format of your sticker design. Please click on Need a custom format now and enter your dimensions in terms of width and height in cm as depicted in the third graphic.

The procedure for round stickers is somehow simpler. First, calculate the diameter (double the radius) of your round sticker design. Gogoprint is able to print round stickers with a diameter of 3 cm up to 10 cm. Please click on Format and select the dimension which is equal to your diameter value as described in the little information text below every option.

3. What are the differences of the sticker material types?

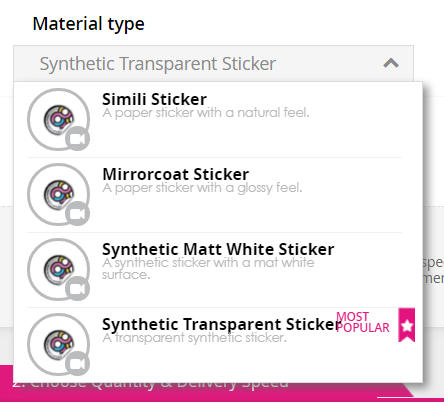

Gogoprint currently offers four material types for stickers:

| Sticker Type | Description | Example |

| Simili Sticker | - Paper material - Smudge proof when it’s written on - Tearable - Non Waterproof - Suitable for indoor application |

|

| Mirrorcoat Sticker | - Paper material - Mirror-like gloss on the surface - Tearable - Not entirely waterproof - Suitable for indoor application |

|

| Synthetic Matte White Sticker | - Plastic-like material - Non-tearable - Waterproof - Suitable for both indoor and outdoor application |

|

| Synthetic Transparent Sticker | - Plastic-like material - Non-tearable - Waterproof - Suitable for both indoor and outdoor application |

|